Ten years ago, at the Keystone BIG Show, a dealer challenged us: “Make a tailgate light bar that doesn’t fail.” At the time, low-cost bars worked initially, but many returned months later with moisture intrusion, wiring faults, and dead LEDs. Despite strong sales, short warranties and premature failures were common across the category.

That challenge drove the development of the Putco Blade® LED Tailgate Light Bar. Instead of iterating on existing designs, our team re-engineered the product from the ground up, prioritizing OEM-grade reliability and vehicle compatibility, complete encapsulation for proper waterproofing, and long-term performance.

Why compare the Blade to the OPT7 Redline, a popular and more affordable option on Amazon? Because price alone doesn’t tell the whole story. Putco products typically cost 3–4 times more than economy alternatives, and customers deserve clear context on the engineering, materials, and support that drive this difference. OPT7 is widely known, aggressively priced, and effectively markets its quality, making it a relevant benchmark.

Our analysis focuses on four areas that matter to most buyers:

1. Functionality

2. Housing & LED Technology

3. Compatibility & Installation

4. Customer Support & Warranty

Functionality

Both the Putco Blade® LED Tailgate Light Bar and the OPT7 Redline are five-function bars designed to enhance rear visibility and deliver a similar everyday experience. Each integrates with vehicle lighting to support running, brake, turn, hazard, and reverse functions, providing full-width illumination across the tailgate.

In terms of fitment, both are available in 60″ and 48″ lengths to accommodate full-size and mid-size pickups. Putco also expands the lineup with additional sizes, including the 18″ Split Blade and 36″ Blade, broadening the applications for headache racks and Jeep JL/JK installations.

Where they diverge is in validation and signaling. The Blade is engineered and validated to SAE/DOT standards, leveraging Putco’s collaboration with major OEMs, including Ford, General Motors, Toyota, and Stellantis. OPT7 does not publish equivalent certification details for the Redline, which limits direct comparison on testing rigor.

Turn-signal behavior is another key difference. OPT7 uses a scanning amber indicator, while the Blade employs a solid-flash signal, available in red or amber, to maintain precise timing with OEM tail lamps across supported vehicles. Scanning patterns can introduce synchronization variability from one vehicle to another. Putco addresses this preference in the Freedom Blade series, which features an advanced control module for customizable sequences (including scanning) while maintaining reliable timing.

Bottom line: if you value documented validation, OEM-level synchronization, and broader fitment depth, the Blade is built to meet that standard. If an animated, scanning look is your top priority, the Freedom Blade offers the style you want with the control you need.

Housing & LED Technology

Housing Construction

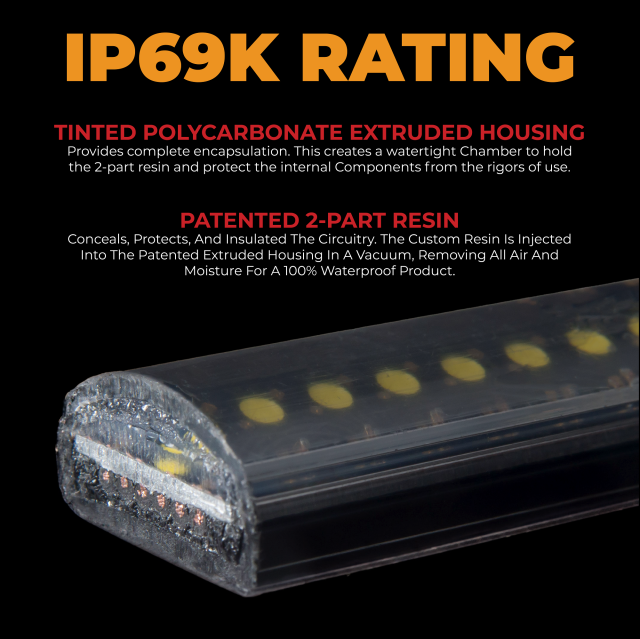

Putco forms the Blade’s housing using a two-color polycarbonate extrusion, creating a single solid-state tube with a clear optical lens and a black rear surface. Because the lens and body are one continuous piece, there are no seams, joints, or exposed substrates, resulting in a fully sealed enclosure that protects the electronics for long-term use.

This monolithic construction delivers practical benefits in real-world use, including high impact resistance, controlled flexibility for easier handling and alignment, and strong resistance to corrosion and environmental wear.

After the housing is formed, compact Chip-on-Board (COB) LED arrays are installed. COB minimizes the circuit-board footprint while concentrating light output and improving thermal stability—points we expand on in the LED Technology section.

The assembly is then fully potted with a high-grade silica resin that fills all internal cavities and cures into a rigid protective barrier. This achieves complete encapsulation of both the housing interior and electronic components. The result is an IP69K rating, the highest protection level for dust and high-pressure, high-temperature water ingress.

By contrast, OPT7’s bar uses an aluminum U-channel with LED boards laid inside and covered by an exposed silicone-based epoxy layer. In our internal evaluation of a new Redline 60″ bar, we observed that modest mechanical pressure could fracture this epoxy, leaving LEDs and circuitry vulnerable to the elements. Because there is no secondary, sealed outer housing, the electronics face a greater risk of damage; the tacky surface can also attract dust and debris, which may diminish light output and increase maintenance needs.

Additionally, the assembly is not fully sealed in the same way as a monolithic tube. Based on these observations, the product’s stated IP67 protection (two steps below IP69K) appears less robust in practice than a fully encapsulated design.

LEDs and Electronics

The Putco Blade® architecture centers on two core electronics: the light bar assembly and the Lighting Control Module (LCM).

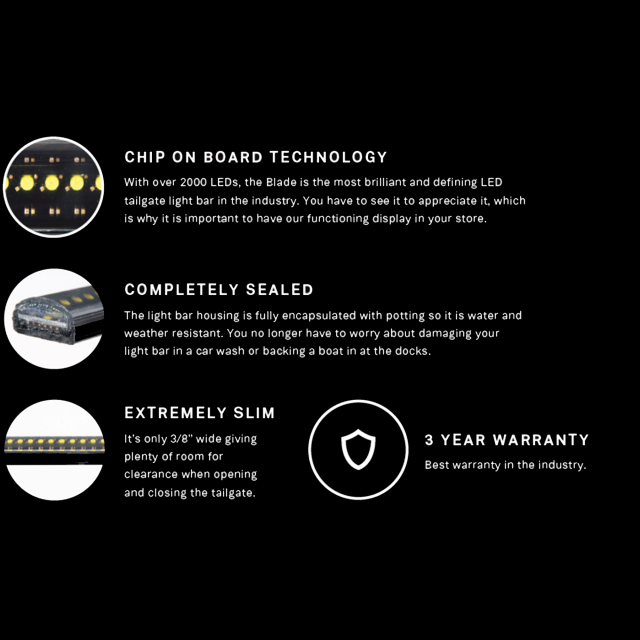

Each Blade light bar uses two black circuit boards populated with dense rows of Chip-on-Board (COB) LEDs. Individual rows are dedicated to each color function—red, amber, and white—ensuring a uniform appearance across the bar. Full-size Blade models contain more than 2,000 COB emitters.

COB technology offers several advantages: a compact circuit footprint that supports a slimmer housing, efficient thermal behavior that eliminates the need for bulky heat sinks, and an extended service life due to fewer solder joints and improved heat dispersion. Packing thousands of miniature diodes closely together also creates the Blade’s signature, continuous “laser-like” light band with minimal visible pixelation. When the bar is off, the dark boards and micro-scale emitters present a discreet, low-profile look that blends into the vehicle.

OPT7’s Redline bar utilizes surface-mount (SMT) LED technology—a capable approach that achieves high brightness and is also employed by Putco in products like the Freedom Blade. However, the larger SMT packages in the OPT7 design are more conspicuous when unlit and typically require a taller housing. That added height occupies more tailgate real estate and can complicate fitment on certain vehicles with limited mounting space, including some late-model Chevrolet and GMC trucks.

Lighting Control Module (LCM)

The Lighting Control Module (LCM)—often called the driver box—is the Blade’s internal logic system. It is central to the product’s compatibility, functionality, and reliability, and you’ll see it referenced throughout this article. By contrast, the OPT7 Redline operates with a simpler, analog-driven approach that omits this dedicated control stage and therefore lacks many of the Blade’s built-in features and safeguards.

Functionally, the LCM acts as the Blade’s “brain.” It interprets vehicle inputs (running, brake, turn, reverse, hazard) and then outputs the appropriate light behavior with precise timing and voltage control. What matters most happens in the microseconds between input and output: the LCM conditions signals, stabilizes power, and manages timing logic so the Blade performs consistently across different vehicle platforms.

While the LCM’s internal design is proprietary, it incorporates redundancies and protections that keep all critical logic inside the driver box. This architecture helps maintain the electrical integrity of the vehicle, reduces the chance of noise or back-feed into factory circuits, and prevents harmful signals from reaching the LEDs. OPT7’s design does not include a comparable control module, which means it does not offer the same level of signal management, protection, or cross-platform consistency.

Compatibility & Installation

Plug & Play Wiring Harnesses

Putco offers plug-and-play wiring solutions for virtually all current Ford, Chevrolet, Ram, Nissan, Toyota, Jeep, and Hyundai pickup trucks – see the charts below for fitment information for 2026 models. Every harness is engineered and validated in-house to ensure precise fit and reliable function on each supported model. By contrast, most OPT7 installations require splicing into the factory tail-lamp wiring.

As an OEM partner to Ford, Chevrolet, Toyota, Nissan, and Stellantis (including Dodge, Jeep, and Ram), Putco develops and verifies its wiring systems in collaboration with OEM engineers at the manufacturer’s facilities. This process confirms full compatibility with factory electrical architectures and helps ensure long-term reliability.

OPT7 has recently introduced a limited harness lineup. The wire colors and layouts closely resemble Putco’s vehicle-specific solutions; however, to our knowledge, these harnesses were developed without OEM collaboration or validation and omit key features—such as a Weather Pack connector on the reverse lead. As a result, they are not fully plug-and-play; the reverse circuit still requires a splice.

Coverage breadth is another differentiator. For fairness, our comparison includes OPT7’s generic 7-way trailer harness as an option for older trucks, even though the company does not market it by model. That approach is increasingly impractical on late-model pickups, as most OEMs have revised their towing and electrical systems after 2018, limiting the compatibility of universal 7-way adapters.

2026 Model Year Fitment

Chevrolet

| Putco | OPT7 | |

| Chevrolet Silverado 1500 | Plug & play installation | Hardwire installation* |

| Chevrolet Silverado 2500/3500 | Plug & play installation | Hardwire installation* |

| Chevrolet Colorado | Plug & play installation | Hardwire installation* |

GMC

| Putco | OPT7 | |

| GMC Sierra 1500 | Plug & play installation | Hardwire installation* |

| GMC Sierra 2500/3500 | Plug & play installation | Hardwire installation* |

| GMC Canyon | Plug & play installation | Hardwire installation* |

Ford

| Putco | OPT7 | |

| Ford F-150 | Plug & play installation | Hardwire installation* |

| Ford F-150 Lightning | Plug & play installation | Hardwire installation* |

| Ford F-150 Raptor | Plug & play installation | Hardwire installation* |

| Ford Super Duty | Plug & play installation | Hardwire installation* |

RAM

| Putco | OPT7 | |

| Dodge RAM | Plug & play installation | Hardwire installation* |

Nissan

| Putco | OPT7 | |

| Nissan Frontier | Plug & play installation | Plug & play installation |

Jeep

| Putco | OPT7 | |

| Gladiator | Plug & play installation | Plug & play installation |

| Wrangler | Plug & play installation | Light bar will not fit |

Toyota

| Putco | OPT7 | |

| Tacoma | Plug & play installation | Plug & play installation |

| Tundra | Plug & play installation | Plug & play installation |

Hyundai

| Putco | OPT7 | |

| Santa Cruz | Plug & play installation | Incompatible |

*May not function properly due to OEM wire layouts and electrical configurations

Internal Logic

A frequent question we hear is: “Why does Putco include the harness with the Blade instead of selling it separately?” The short answer is compatibility and long-term reliability with OEM electrical systems.

Unlike OPT7, which sells a universal bar and adapts it across vehicles with modified instructions, Putco engineers each Blade as a vehicle-specific system. Although the bars look identical when installed, the Lighting Control Module (LCM) inside each Blade is uniquely programmed to interpret that vehicle’s signals. This approach preserves precise timing with factory tail lamps, helps prevent fuse or fault events, and maintains full compatibility with OEM electronics.

By contrast, OPT7’s design does not incorporate an external LCM. While that simplifies packaging, it limits the product’s ability to accommodate vehicle-to-vehicle signal differences. The result can be timing inconsistencies or electrical conflicts that reduce functionality. In some cases, installers may need to sacrifice either the brake or turn function because different vehicles deliver those signals in distinct ways.

Mounting the Light Bar

OPT7 ships its light bar with generic double-sided tape applied along the full length of the unit. The tape is neither branded nor specified, which makes long-term adhesion performance difficult to evaluate.

Putco takes a different approach. Every Blade utilizes genuine 3M automotive-grade tape, paired with patented, injection-molded mounting clips. The clips can be installed using the included 3M tape or, if preferred, with self-tapping hardware through the clip’s center slot. While we generally recommend the tape method, the hardware option is available for customers who want a mechanical fastener.

This clip system provides a practical service advantage: the Blade can be unclipped at any time to access the spare-tire release without damaging paint or the light bar, and it returns to its exact position when reinstalled. Removal and reattachment take seconds, preserving alignment and appearance.

By contrast, OPT7’s tape-only method—with roughly 60 square inches of adhesive contact—makes removal difficult and increases the risk of damage to both the vehicle and the light bar during service. In real-world scenarios, when a spare tire needs to be accessed, the tools and solvents required to release automotive tape safely are rarely on hand.

OPT7 sells an optional magnet accessory that adheres to the taped bar, but the holding strength is unspecified and it is incompatible with aluminum-body trucks, such as many late-model Ford pickups.

Customer Support & Warranty

Customer Support

Based in Des Moines, Iowa, Putco operates from a U.S. manufacturing facility with an on-site customer service and technical support team available Monday through Friday, 8:30 a.m.–5:00 p.m. CT. Customers can reach us by phone, live chat on Putco.com, or email. Calls are answered by Putco staff in our building—no call centers or outsourcing—so you’re speaking directly with the people behind the product.

Customers can reach us in three ways:

Phone: Calls are always answered by real Putco staff inside our building – no call centers, outsourced agents, or robots between you and our people.

Live Chat: Available on Putco.com for quick, in-browser support.

Email: Send us a message anytime for detailed responses and documentation.

Every team member is factory-trained to provide installation guidance, troubleshooting assistance, and answers to general product questions. For more complex needs, our technicians can initiate live video support for real-time diagnostics and setup. The support team works closely with Putco engineering, enabling quick escalation and resolution of uncommon or highly technical issues.

By contrast, OPT7 lists only a single contact method—an online submission form that advises “please allow three business days for a response.” No phone number, live chat, or alternative contact options are provided.

Choosing Putco means you’re backed by responsive, knowledgeable support from the same team that designs and builds your product.

Warranty

Putco builds a premium product and stands behind it. Every Blade is covered by a three-year warranty with a straightforward, customer-friendly process. Once a claim is approved, we ship a replacement directly to you at no cost—Putco covers the product and the shipping. Most claims are processed within 24 hours, and if the item is in stock, it typically ships the same day. In many cases, submissions received in the morning are fulfilled by the afternoon.

According to OPT7’s website, its light bars carry a one-year warranty, covering defects only. Processing typically takes 1–2 weeks, and customers are responsible for shipping costs, which average $30–$50. OPT7 also offers an optional “Prime Warranty” upgrade for approximately $15, which shortens processing time to 3–4 days and includes shipping coverage.

Putco will never charge extra for basic customer service or warranty handling. Our goal is straightforward: to provide fast, hassle-free support that gets you back on the road with minimal downtime.

Conclusion

In conclusion, the Putco Blade® LED Tailgate Light Bar is the premium choice for buyers who value long-term performance. Its monolithic construction, advanced control logic, vehicle-specific compatibility, and streamlined installation combine to deliver reliability that cheaper, universal bars struggle to match.

This performance is the culmination of over a decade of continuous innovation and close collaboration with OEM partners. And it’s backed by responsive, factory-trained support from the same team that builds the product—ensuring a confident experience from purchase through final installation.

If you care about solid build quality, reliable performance, and a clean, factory-style look, the Putco Blade is an easy choice. It genuinely feels like it belongs on the truck, not something that was added later. If you’re only after the cheapest tailgate light, there are plenty out there, but none match the Blade for brightness, durability, or overall feel. It’s one of those upgrades that makes your truck safer and better-looking every time you drive it.

Yes, the Blade costs more than a lot of other tailgate light bars, but you can see where the money goes. The quality, brightness, and overall design make it a worthwhile investment. It’s not a “cheap mod” it’s a serious lighting upgrade that actually improves visibility and safety.

I’ve had a really disappointing experience with the OPT7 Redline tailgate light bar. The wiring is overly complicated, and trying to get all the functions to work correctly is a NIGHTMARE. Apparently, many people experience the same issue, where the brake light or turn signals won’t sync properly, regardless of how carefully they’re installed, but the company hasn’t done anything to make the product better or easier. I tried to reach out to the company for help, but their customer service team never got back to me! I finally gave up on it and made the switch to Putco’s Blade, and I have loved my new Blade light bar and their AMAZING customer service team!